How Does Series/Parallel Shifting Work?

I’m confused- how does the series to parallel switch happen and how does it enhance motor power and amp consumption?

Thks

Rush

Tucson AZ

Hi Rush,

Here is a snippet from the EV list some time ago. I’ve tried to edit it a bit for clarity.

EVList Post from 2004 follows:

OK. Let’s think about this a bit. Why did Otmar chose to shift at

1/2 the peak amps (and are we talking battery or motor amps,

anyway?)?

Let’s assume it is *motor* amps that determine the shift point. When

the motor amps drop to 600A in series mode, and the controller shifts

to parallel, the motor amps stay the *same* provided there is enough

battery voltage available to push the controller back into current

limit. RPM doesn’t change instantaneously, so there is no stair step

in power; the shift to parallel just makes full pack voltage

available to each motor so that they can continue to build speed

while amps/torque continues to fall off.

I know Otmar is trying to follow this thread, so perhaps if I haven’t

put him to sleep already he can chime in with a proper explanation of

how/why the ‘Zilla implements series-parallel shifting…

Otmars Response follows:

I should mention to the uninitiated that this shifting involves utilizing the Hairball to drive contactors switching two motors electrically from series to parallel configuration. It is sometimes used in dual motor cars when trying to get the best acceleration out of a system while avoiding the higher cost of buying two controllers. It is mostly used with Z2K’s since high voltage Z1K systems do not gain as much unless the batteries sag quite a bit under load. In series mode the two motors can see up to half of the available battery voltage (don’t forget to take into account battery voltage sag) and each gets the full motor current. In parallel mode the motors can each be supplied with up to the full battery voltage but each gets only half of the available current from the controller. Parallel mode can allow both motors to draw more power when they are spinning at higher RPM.

The operation is pretty much just as you said. Initially I had the shifting happen at a certain adjustable RPM, but that’s inefficient on the street and does not compensate for battery temperature and state of charge, so I devised the auto shift algorithm and left the option of a manual shift for those who want to experiment.

When the Hairball is set to Autoshift mode it works like this:

It starts in series mode for maximum torque and for lower controller current in regular driving. Then, when you put the pedal to the metal the Hairball starts to pay attention.

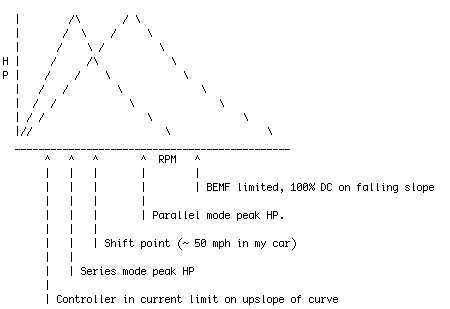

In order to initiate a shift to parallel, the first requirement is that the controller is at 100% duty cycle. (this is the right side of the mountains shown below) This means the controller is full on the battery amps equal the motor amps. If the controller were still acting as a transmission then there would be no reason to switch the motors yet since the resulting power would be less after the shift.

After reaching 100% duty cycle, the motor and battery amps are dropping as the vehicle speeds up.

A simple way to view the HP to RPM curve of a series motor in a EV is to imagine it as a mountain. The upramp of the curve is the controller in current limit, the downslope on the high RPM side is when the controller is full on and the motor BEMF (Back Electromotive Force) is limiting power.

In order to maximize the power under the curve, I believe you want to shift when the falling series curve of motor power vs rpm crosses the rising curve of the motors in parallel. This turns out to be when the series mode current is half of what would be available after the shift.

Here’s a bit of ASCII art.

View with fixed width font like Courier.

By the way, it’s interesting to note that these curves look same as the power curves seen when shifting a mechanical transmission. The big difference being that with a mechanical transmission the loads on the motors and controller are lower and so mechanical shifting is usually preferred.

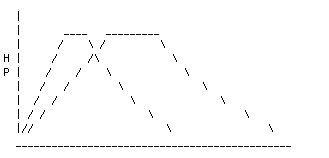

Just FYI here are the same curves when the battery current limit is lower than the motor current limit. The lower the battery current, the less important the actual shift point timing becomes.

I hope this helps

-Otmar-