Q: Now that I have the car running with the Zilla, how should I adjust the battery and motor settings?

A: In general, higher current produces more heat in the batteries, motor and interconnects. Most failures in EV’s are caused by too much heat buildup. Adjusting the limits that are stored in the Hairball can help prevent premature failure of your EV.

We ship the Zilla package set for wide open full power operation. While this is good for making sure it runs right out of the box, it will usually destroy parts of your car if adjustments are not set correctly.

Please note that the Hairball has a “Valet” mode that allows you to quickly switch between two sets of settings on the fly. See the owners manual for more detail on where to connect a valet switch.

Before setting current values, insure that option ‘p’ in the Options menu is ‘on’ if you have a Z1K and ‘off’ if you have a Z2K. Changing this setting will change the set values for current limits.

Be aware that although Hairball settings are close, they are not very precise. It is always good to check the effect of the adjusted settings with a meter while driving since some settings (especially the LBV) will start limiting a bit before the actual set voltage is reached in order to provide smooth response.

Hairball settings all limit maximum and minimum values. This will help prevent failures to a large extent but since there is no feedback from the various temperatures on the vehicle there is no way to insure that damage will not happen from extended operation below the peak limits. That protection needs to come from the vehicle design on lower performance vehicles, and proper instrumentation and operator awareness in higher performance vehicles.

In this article I am assuming the most common street EV conversion setups. Suggested values should be tailored to your components. Unfortunately good data is often hard to come by, therefore it may require instrumentation and tests to determine safe limits.

Battery Menu:

In most EV’s, batteries are the weak link. If you draw too much current from the batteries and in the process of drawing that current the voltage sags too low, the batteries will be damaged. If the draw is much too high the internal connections in the battery will melt and the batteries can blow internally or explode. Drag racers are used to running near these limits and likewise do not expect to get long life from batteries. If your current draws are high, but not so high as to cause catastrophic failure then there is still the risk of greatly shortening the life of the batteries by abusing them with high currents and deep discharges. This is why it is important to set limits for your particular setup. Higher power batteries, those with low internal resistance, will tolerate high current draws better and last longer while putting out high power. Low power batteries such as the flooded golf car type or large format low power lithium cells can provide low cost of ownership but can not supply high power without risking damage. The Zilla has three settings to help protect the batteries. How you set those settings depends on how much power you require and how much battery life you expect.

The first setting in the Battery Menu is “Battery Amps”. This is a limit on the current that the Zilla will draw from the batteries when other conditions permit. High values here can damage your batteries but also can directly relate to higher power. Racers will often run this value as high as possible while street cars are set lower. A car running golf car batteries would run this in the range of 300 to 600 Amps while a racer running AGM or high power lithium batteries may run it between 1200 and 1800 amps. If your battery voltage limit is set high, then the controller may never reach the battery current limit before the voltage limit becomes active. Battery current never exceeds motor current, so if your motor current limit is lower than the battery limit the motor current will be the limiting factor.

The second setting in the Battery Menu is “Low Battery Volts”. The controller will automatically reduce the output current so that the battery voltage does not run below this value. This is a very useful setting for obtaining maximum power when racing and also for protecting batteries in normal street use. A very conservative setting for this is obtained by multiplying your nominal pack voltage by 87%. If your pack consists of 13 batteries that are 12V each, then you have a 156V pack and a very conservative setting would be 136V. A more common setting to insure reasonable power is 75% of the nominal pack voltage, this would be 117V for a 156V nominal pack. For those looking for absolute maximum power from the pack, that can be obtained at 55% of pack voltage, but beware that this will produce massive heat in the batteries and likely will cause failures. The Zilla may limit battery voltage as much as ten volts above the set value depending on the motor current so be sure to verify this value with a meter while driving under load and adjust it as needed to meet your target.

Be aware that LBV only sets the minimum pack voltage. It is likely that the battery pack will not be perfectly matched and so a weaker cell will fall below the average cell voltage. People generally set settings more conservatively in order to account for weaker cells.

The third setting in the Battery Menu is the Low Battery Voltage Indicator. This setting determines at what pack voltage the dash battery light turns on. The battery light on the dashboard should be connected to the ‘Battery Lt Out’ on the Hairball. This is a very helpful simple indicator for showing the state of the battery while driving. I like to set the LBVI value at 87% of pack voltage, or just slightly above the LBV setting, whichever is higher. That way it is easy to see when the battery is being stressed by low voltage. If this light starts coming on during light acceleration then it is clear that the pack is at a low state of charge or has a problem.

Motor Menu:

Motor current is proportional to motor torque. Naturally, high current is desirable for high power. Higher current also produces much more heat. As with many circuits in an EV, it’s handy to remember that the heat produced in Watts is equal to the current in Amps squared which is then multiplied by the resistance in Ohms. Assuming the Ohms are constant, doubling the current quadruples the heat produced. Series wound EV motors generally fail from heat in two areas. Winding heat can get hot enough to melt the polyester insulation when the motor is slightly overloaded for a long time. Also brush and commutator temperatures can quickly overheat and damage the commutator within seconds. Brush temperature rises quickly with high current levels and especially quickly if the motor voltage is high enough to cause arcing or flashover at the brushes. Major brush flashover from excessive motor voltage often makes itself known with a bang that sounds much like a backfire in a ICE vehicle. In case of a flashover, it is imperative to inspect all the bushes, springs and surrounding area for damage before continuing to drive.

Racing EV’s and single ratio street machines should be equipped with at least one brush temperature gauge with a 230 deg C redline. A piece of cheap fiber optic cable pointing at the trailing edge of the brush which is visible in a dark tube on the dash can do wonders for monitoring brush arcing.

For a typical street conversion running a 8″ or 9″ motor, I run the motor current limit between 500-600 Amps. Higher than that often results in a slipping clutch and increases motor heating as well. I have tested Advanced DC motors in 8″ and 9″ sizes in standard and XP models and have found that with perfectly broken in brushes in race situations the motor voltage can be set as high as 170 Volts without causing flashover. In street applications I suggest limiting them at 150 Volts. Other motors may have different limits, but I have seen little actual test data on them at high voltages.

Reverse settings become active when there is power connected to the ‘Reverse Input’ on the Hairball. Amps should be set high enough to allow enough torque to back out of a steep situation and reverse volts can be set low in order to limit reverse speed.

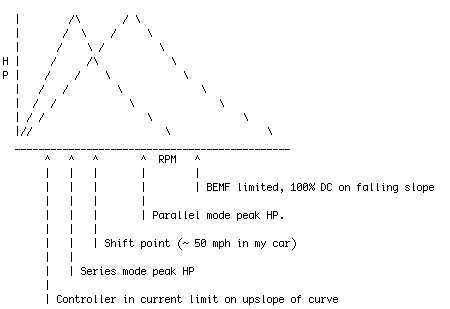

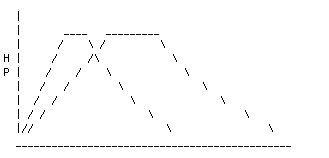

Parallel settings are only used in dual motor setups that are wired for S/P switching. Parallel is normally used at high speed to get extra power. Usually this happens over 40 MPH on single ratio direct drive vehicles. The limits set in the Hairball are what the controller supplies to the motor circuit, so if you want to limit average motor current of two motors in parallel to 800 Amps, then the parallel setting should be set at 1600A. To limit the average voltage of two motors in series to 150V, the standard series voltage limit should be set to 300V.

Speed Menu:

Speeds are a simple and abrupt limiting value. The normal and reverse limits should be set low enough to protect the motor. The ‘Max’ setting does not limit speed by itself, it only logs a error so that one can tell in the future if the set speed was exceeded.

-Otmar